Work Head

Most of the machining for the work head parts was completed. The fit of the Tool Head (#303) to the Spigot (#319) was not close enough for my tastes. Also the length of the spigot fell short of the bottom of the bore in the bronze bracket (#302). Compared to the rest of the parts I assume the spigot in the box of parts was a fixture for machining the tool head. This is the only thought that makes sense to me.

Tool head on arrival (LH) and the bronze pivot bracket (RH)

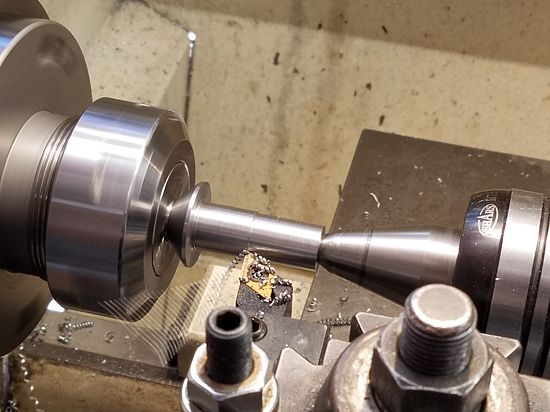

I used a piece of leaded steel and turned down the lower shaft for a tight fit on the bronze casting. Reversing the part in the chuck I then turned down the upper shaft for a snug fit on the tool head disk.

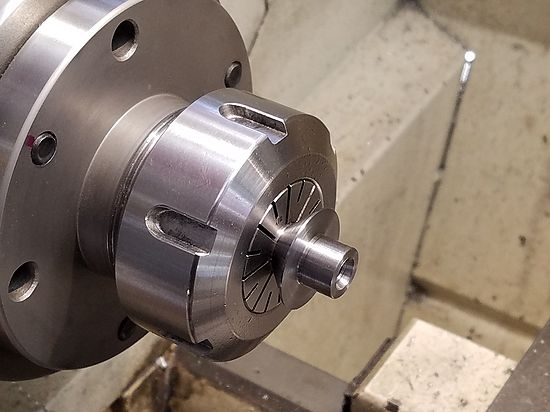

A small washer with a relief on the bottom was machined to hold the disk and spigot together. The pivot bracket was bored to fit the stub shaft, radius ground to match the and then polished to a final finish.